About Us

WE ARE

RECON INSPECTION

Your trusted partner for industrial maintenance and inspections in Canada.

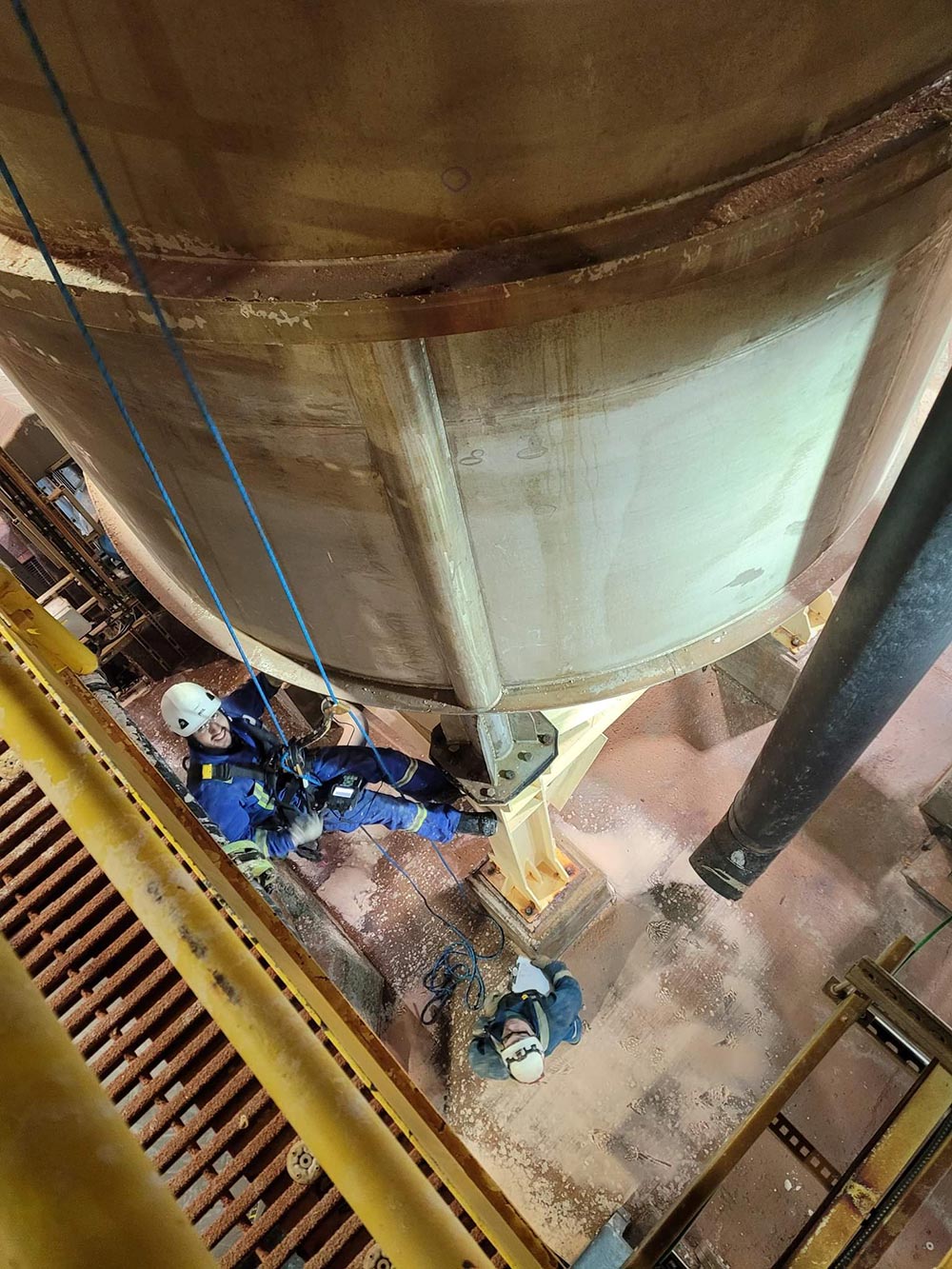

Recon Inspection is a Canadian Industrial maintenance company with a shop and training facility based in Saskatoon, Saskatchewan, Canada. Recon Inspection specializes in the maintenance of mining facilities, processing plants, refineries, mills, plants, batteries, and specialized production sites. Our motivated team has a broad range of inspection and repair experience in conjunction with API certifications in CWB welding, Irata rope access accreditation, and CGSB compliant non-destructive testing technicians with in-house level 3 expertise in various fields. Our technicians will ensure that facilities make the appropriate repairs when and where they are required to ensure compliance during on-going operations.

Recon technicians have performed work throughout Canada on various turnarounds, shut-downs, maintenance and emergency jobs, on any day or night shift, while minimizing any limitations based on weather conditions and access by using our combined expertise and work ethic.

At Recon we used advanced rope access techniques with and our combined experience to minimize limitations and our company work ethic has allowed us to complete large scale jobs with teams of 50+ technicians over the last 14 years without any major safety incidents resulting in harm to any of our valued workers. We are confident that we have the best team in Canada, particularly in the Canadian prairie region.

Our Services

Visual Inspection

Conducted in compliance with API, CWB, and client standards, our visual inspections cover a wide range of industrial applications.

Rope Access & UT Evaluation

We offer specialized inspections of HDPE piping, ensuring compliance with API 570 and client requirements.

Pressure Equipment Inspection

Our visual and UT inspections are performed in accordance with API 510, providing critical insights for maintenance and safety.

Structural Components Inspection

We assess structural components and offer short-term and long-term repair planning to maintain the integrity of your assets.

Why Choose Recon Inspection?

- Experienced in a wide range of industrial maintenance services.

- Certified and accredited technicians for enhanced safety and reliability.

- Proven expertise in industrial inspections and repair projects.

- Dedicated to minimizing downtime and ensuring compliance.

At Recon Inspection, our mission is to provide the highest quality of industrial maintenance, inspections, and repair services to our clients across Canada. We are dedicated to maintaining the integrity and efficiency of your facilities, ensuring they operate smoothly and safely.